GFM Systems

COLD-WARM-HOT – FORMING

GFM technology, the true innovation for your specific applications and material characteristic.

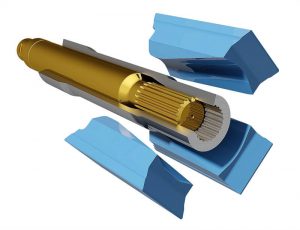

COMBINED AXIAL- RADIAL FORMING

Upsetting and swaging in one step, to gain the ideal geometry of your workpiece.

SWAGING – A FLEXIBLE FORMING VARIATION

Short cycle times, ideal grain flow and best surface quality – are potential considerations for material- and weight savings, as well as use of low cost material grades.

RADIAL FORGING

High alloyed steels have been successfully formed for decades on GFM radial forging machines. This forming procedure is best suitable for working with exotic alloys as well as composite materials.

FLEXIBILITY

GFM develops forming technologies for new applications, while the forging machine remains basically unchanged. This offers our customers the capability of producing new parts by adapting the forging tools and programs only.

DEVELOPMENT COMPETENCE

We assist our customers in all phases, from conceptive design, to process development, up to prototype and the initial production forging.